Tungsten carbide is widely recognized as “hidden gold” in the industrial world due to its exceptional value and applications. This ultra-hard material is commonly found in cutting tools, machinery, and industrial components, yet it often ends up as underutilized waste.

In fact, recycling tungsten carbide offers significant benefits—both economically and environmentally. This article will discuss what tungsten carbide is, why it is so valuable, and how to identify and recycle it from your industrial waste so it doesn’t go to waste. Let’s discover the true potential of this industrial treasure.

1. What Is Tungsten Carbide?

Tungsten carbide is an inorganic compound made from equal parts tungsten (W) and carbon (C). In its raw form, it appears as a fine gray powder that is compacted and shaped through a sintering process to produce components. Its strength and hardness make it one of the toughest industrial materials in the world, ranking close to diamond on the Mohs scale (9.0–9.5).

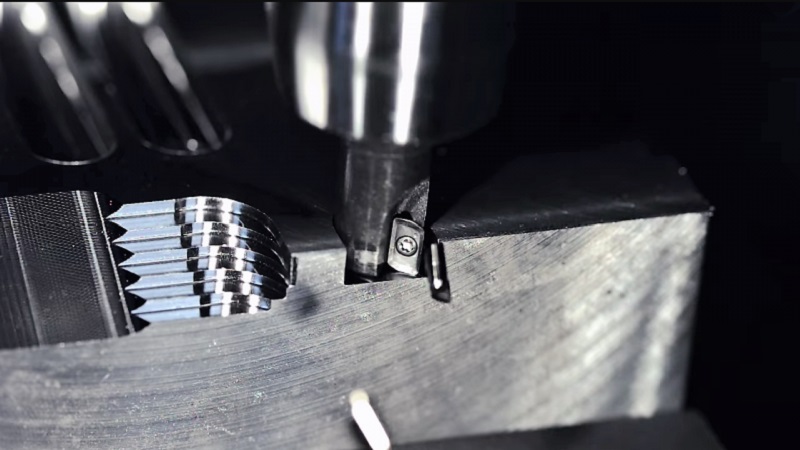

With double the density of steel and three times the stiffness, tungsten carbide resists wear and deformation. This makes it ideal for precision cutting tools, heavy-duty machine components, and specialized applications that require extreme durability. In industrial contexts, it’s often simply called “carbide,” though it comes in various forms.

2. Key Properties and Advantages of Tungsten Carbide

The unique value of tungsten carbide lies in its outstanding hardness, strength, and durability. Key advantages include:

- Extreme Hardness: Retains sharpness at high temperatures, ideal for cutting tough metals.

- High Compressive Strength: Resists cracking under extreme pressure.

- Wear and Corrosion Resistance: Lasts much longer than steel.

- Thermal Conductivity: Reduces overheating risks during high-speed operations.

- High Density: Ensures tool stability and precision performance.

These properties make tungsten carbide a long-term “investment,” helping industries cut costs on tool replacement and maintenance.

3. Where Can You Find Tungsten Carbide?

Although often overlooked, tungsten carbide is everywhere in industrial settings. Common examples include:

- Drill bits for metal, concrete, and stone

- Lathe and milling inserts for metal cutting

- Endmill cutters in manufacturing

- Mining drill teeth for crushing rock and minerals

- Medical instruments like surgical scissors and dental drills

- Tungsten carbide jewelry such as scratch-resistant rings

Many of these components, once worn out, are discarded as waste—even though they hold significant recycling value.

4. Why Is Tungsten Carbide So Valuable Globally?

Tungsten carbide commands a premium price in global markets due to:

- Raw Material Scarcity: Tungsten is rare and mined in limited regions like China, Russia, and Canada.

- Complex Production: Manufacturing requires advanced technology and high-heat processing.

- High Demand: Used in mining, oil & gas, precision manufacturing, and defense.

- Long Service Life: Durable tools reduce replacement frequency.

- Recycling Potential: Scrap tungsten carbide can be reprocessed into new, high-quality material.

This balance of limited supply and high demand keeps tungsten carbide prices stable at premium levels.

5. Industrial Applications of Tungsten Carbide

Tungsten carbide is used across multiple industries, including:

- Manufacturing: Drill bits, lathe tools, endmills, and metal molds

- Mining: Drill teeth, rock-crushing tools, and coal-cutting blades

- Oil & Gas: Valve components, seals, and deep-sea drilling tools

- Medical: Precision surgical instruments and dental equipment

- Defense: Armor-piercing ammunition and weapon components

- Automotive & Transport: Protective coatings for high-performance brakes

- Jewelry: Scratch-resistant rings and bracelets

6. The Hidden “Gold” Potential of Tungsten Carbide Scrap

Factories and workshops often throw away worn inserts, drill bits, or broken carbide components without realizing their value. These scraps can be sold to specialized recycling companies at profitable rates.

Recycling typically involves:

- Collection: Separating tungsten carbide from other materials.

- Processing & Refining: Converting it back into WC powder.

- Reproduction: Using the powder to create new tools.

By recycling tungsten carbide, industries save money while reducing the need for new tungsten mining—supporting environmental sustainability.

7. Tips for Identifying and Managing Tungsten Carbide Scrap

To avoid discarding this industrial “gold,” follow these steps:

- Check Weight & Density: Tungsten carbide is much heavier than steel.

- Inspect Color & Texture: Usually metallic gray or black with a smooth surface.

- Look in Key Components: Drill tips, lathe inserts, or mining drill teeth.

- Separate from Regular Waste: Store in a dedicated container for resale.

- Work with Professional Recyclers: They have the technology to process WC into reusable material.

By applying these tips, you can maximize the value of every unused piece of tungsten carbide.

Tungsten carbide is an extraordinary material with diamond-like hardness, used in countless industries, and valued highly in global markets. Unfortunately, much of it ends up as waste—when in fact it can be recycled into new, high-performance products.

For those in manufacturing, mining, or machining, recognizing and recycling tungsten carbide scrap is a smart move—both financially and environmentally. With its long-term benefits, tungsten carbide recycling truly is the hidden gold of the industrial world.

Source: