Recycling carbide waste is not just an activity for financial gain—it is also a crucial step in preserving the environment. Carbide, widely used in the manufacturing industry due to its strength and durability, can become a serious problem if left to accumulate as waste.

Through proper recycling processes, this waste can be reprocessed into useful materials, reducing the need for raw resource exploitation while minimizing pollution impacts. This article will explore how recycling carbide waste not only holds economic value but also provides significant benefits for sustainability and environmental health.

Reducing Waste and Environmental Burden

The manufacturing industry is known as a major contributor to metal waste. Every year, factories and workshops produce millions of tons of metal scraps from production processes and tool replacements. One of the main causes is the short lifespan of conventional cutting tools, which wear out, break, or become dull quickly and thus require frequent replacement.

Ordinary steel tools, although cheaper at first, have shorter service lives. Each time a tool breaks, its leftover material adds to solid waste. If discarded carelessly, this waste ends up in landfills, pollutes the environment, and wastes valuable resources.

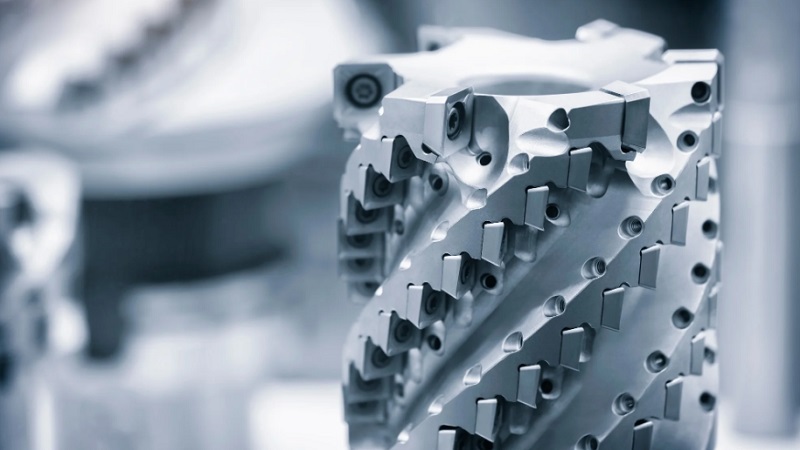

This is where carbide and HSS (High Speed Steel) come in as solutions. Both materials are highly durable, with carbide in particular being nearly as hard as diamond. Their lifespan can be five to ten times longer than conventional steel. This means fewer tool replacements, reduced waste generation, and lower demand for new production.

More importantly, recycling carbide and HSS waste prevents the accumulation of non-degradable metal waste. This process not only saves landfill space but also reduces the risk of soil and water contamination from corrosion or chemical reactions of discarded metals. The more companies adopt recycling programs, the greater the positive environmental impact.

By embracing recycling, companies indirectly shift from a linear production model—“take, use, discard”—to a circular production model that maximizes resource reuse.

Conserving Natural Resources and Energy

Every cutting tool manufactured requires raw materials such as tungsten, cobalt, iron, nickel, and chromium. To obtain them, industries rely on mining operations. Metal mining consumes vast amounts of energy, generates carbon emissions, and often leaves behind toxic waste that can harm ecosystems.

By recycling carbide and HSS waste, we can reduce the demand for new raw materials. The valuable content within these wastes, such as tungsten carbide, can be processed back into powder or used as raw material for new tools—without additional mining. Every kilogram of recycled metal translates into significant resource savings.

Read More: Understanding Tungsten Carbide: The Hidden “Gold” in Your Industrial Waste

Energy conservation is another major benefit. Producing tools from recycled materials typically requires far less energy compared to producing them from raw ores. Mining, refining, and smelting new metals are extremely energy-intensive. By reducing these steps, we also cut greenhouse gas emissions that contribute to climate change.

Some cutting tool manufacturers have already adopted closed-loop manufacturing systems, in which they collect carbide and HSS waste from customers, recycle it, and reuse it to produce new tools. This keeps materials in the production cycle as long as possible and reduces dependence on new raw supplies.

Beyond efficiency, this is a tangible way for industries to contribute to global environmental sustainability. Every ton of recycled carbide waste represents a step forward in lowering the carbon footprint of the manufacturing sector.

Supporting the Circular Economy and Adding Economic Value

Recycling carbide and HSS waste is a real-world application of the circular economy—a concept where products and materials are used for as long as possible, their maximum value is extracted, and at the end of their lifecycle, they are regenerated into new resources.

For businesses, selling carbide and HSS waste is not just about generating extra income—it’s also a sustainable business strategy. The resale price of carbide scrap is relatively high due to its valuable metal content. By collecting and selling it, companies gain additional revenue that can be reinvested into operations, product development, or innovation.

Moreover, many suppliers and tool manufacturers offer incentive programs for returning carbide and HSS waste. Some even provide discounts or rebates on new purchases when customers return their scrap. These systems encourage workshops and companies to actively participate in the recycling supply chain.

From an environmental perspective, each scrap transaction reduces the need for new raw material extraction. From a business perspective, it’s a smart step toward lowering long-term costs. While carbide and HSS tools have higher upfront costs, their longer lifespan and resale value result in a lower total cost of ownership (TCO) compared to regular steel tools.

This shows that sustainability does not have to sacrifice profitability. In fact, sustainability and profitability can go hand in hand. Companies that manage their metal waste effectively also build a positive reputation among customers, investors, and business partners. In today’s world, where environmental awareness is rising, being recognized as an eco-conscious company is an invaluable asset.

Recycling carbide and HSS waste offers benefits far beyond financial profit. This practice helps reduce waste and pollution, conserve natural resources, lower energy consumption, and promote a circular economy that benefits all stakeholders.

For the manufacturing industry, it is a strategic step toward a more efficient, eco-friendly, and sustainable future. For the environment, it is a way to reduce the strain on our planet, which is already under pressure from excessive resource exploitation.

By adopting recycling as part of their business process, companies not only achieve profitability but also leave behind a healthier planet for future generations. The world does not need more waste—it needs smart solutions like carbide recycling and HSS waste management.

So, how is it? Is everything clear about recycling carbide and HSS? Hopefully, you’re no longer confused about topic of recycling carbide!

Source: