The manufacturing sector in Indonesia is currently undergoing a major transformation. This change is driven by three key factors: the advancement of Industry 4.0, global sustainability issues, and the growing environmental awareness among consumers. In the past, manufacturing was primarily focused on production efficiency and output volume. Today, however, companies are required to consider the long-term impact of every production process they run.

One concept that is becoming increasingly relevant is the circular economy. This concept not only helps companies achieve sustainability but also opens new opportunities to enhance competitiveness in the global market. As one of Southeast Asia’s largest industrial bases, Indonesia holds a strategic position to lead this transformation.

What Is a Circular Economy?

A circular economy is an economic system that emphasizes reducing waste, reusing materials, and recycling products to create a sustainable production cycle. This model differs from the traditional linear economy, which has long dominated—“take, make, dispose.”

In the context of Indonesia’s manufacturing industry, adopting a circular economy means companies must consider not only how a product is manufactured but also how it is used, recycled, and ultimately returned as raw material. In this way, the value of a product does not end with the consumer but continues to circulate within the industry cycle.

The Importance of Recycling in the Industry 4.0 Era

Industry 4.0 brings a digital revolution with massive impact on manufacturing. Technologies such as smart sensors, the Internet of Things (IoT), artificial intelligence (AI), and big data allow companies to manage waste in smarter and more efficient ways.

For example, smart sensors on production lines can detect materials that can still be reused before being discarded as waste. Big data enables companies to predict consumer demand patterns, allowing production volumes to be adjusted more precisely and reducing potential waste.

Through these technologies, Indonesia’s manufacturing sector can adapt more effectively to global consumer trends that favor sustainable products. As consumers in Europe and the United States increasingly choose items labeled “eco-friendly” or “recycled material,” Indonesian manufacturers applying circular economy principles can more easily access and compete in those markets.

Opportunities for Manufacturing Companies

The adoption of the circular economy creates multiple strategic opportunities for Indonesian manufacturers, including:

- Production Cost Efficiency

By recycling waste, companies can reduce dependence on imported raw materials with fluctuating prices. For example, plastic waste can be reprocessed into packaging material, while metal scraps from cutting processes can be remelted for reuse in production.

- New Product Creation

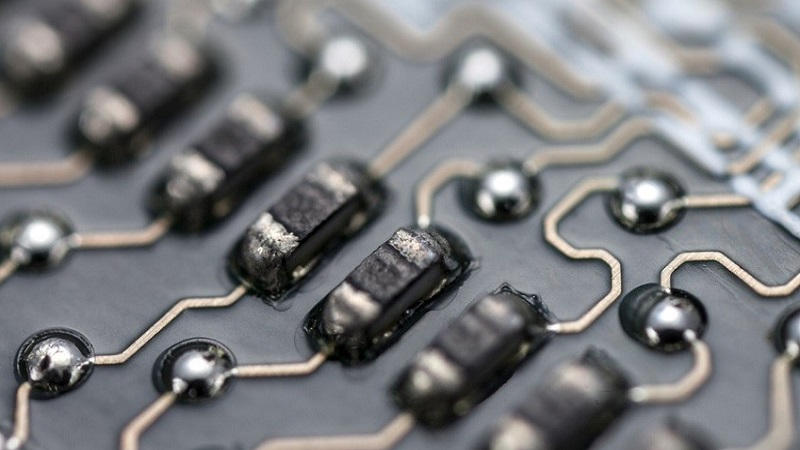

The circular economy drives innovation. Electronic waste, for instance, can be processed to extract valuable metals such as Tantalum, Tungsten, and copper, which are crucial for high-tech industries. Companies that succeed in extracting added value from waste gain a competitive edge.

- Job Creation

A recycling ecosystem creates new value chains. From collection, sorting, and processing to the distribution of recycled materials, each stage holds the potential to generate new jobs that support the national economy.

- Access to Global Markets

International markets increasingly prioritize environmentally friendly products. By applying circular economy principles, Indonesia’s manufacturing industry can meet global sustainability standards and expand exports to Europe, the U.S., and East Asia.

The Role of Government and Regulation

The Indonesian government plays a critical role in driving the adoption of the circular economy. Through its “Indonesia Emas 2045” vision, sustainability has been placed as a central pillar of long-term development.

Some key initiatives include:

- Green Industry Policies, encouraging companies to reduce carbon emissions and adopt renewable energy.

- Tax Incentives and Subsidies for companies developing eco-friendly technologies.

- Public-Private Partnerships to build recycling infrastructure, such as plastic waste and e-waste processing centers.

With the right regulations, Indonesia’s manufacturing sector can accelerate its transformation toward a sustainable economic model.

Challenges That Must Be Addressed

Despite its great potential, implementing the circular economy in Indonesia faces several challenges:

- Unequal Infrastructure

Modern recycling facilities are still concentrated in major cities. Many industrial regions outside Java lack access to advanced recycling technologies.

- Consumer Awareness

Indonesian consumers remain accustomed to linear consumption patterns. Education is needed to encourage waste separation and support for recycled products.

- High Initial Investment Costs

Building recycling systems and adopting smart technologies requires significant capital. Not all companies, especially SMEs, can afford these investments without government or strategic partner support.

However, these challenges are not permanent barriers. With the growing global push for sustainability, companies that adapt will gain greater long-term benefits.

The Future of Indonesia’s Manufacturing Industry

If the circular economy is widely implemented, the future of Indonesia’s manufacturing sector will be stronger and more competitive. Possible outcomes include:

- Greater Global Market Acceptance: Developed countries are becoming increasingly selective. Sustainability labels will become the key to penetrating European and American markets.

- Efficiency and Innovation: Companies will reduce production costs while developing new products from recycled materials.

- Positive National Image: Indonesia can build its reputation as a modern, competitive, and environmentally responsible industrial hub.

- Raw Material Independence: Recycling will reduce dependence on imports, strengthening national economic resilience.

The circular economy represents the future of Indonesia’s manufacturing industry. With Industry 4.0 technologies, companies can manage waste more intelligently, cut production costs, and create new value. Challenges do exist, from limited infrastructure to consumer awareness, but the opportunities are far greater.

If applied consistently, the circular economy will make Indonesia’s manufacturing sector more competitive on the global stage—not only producing high-quality goods but also enhancing its reputation as a nation committed to sustainability. This will ensure a more inclusive, resilient, and future-ready industry.