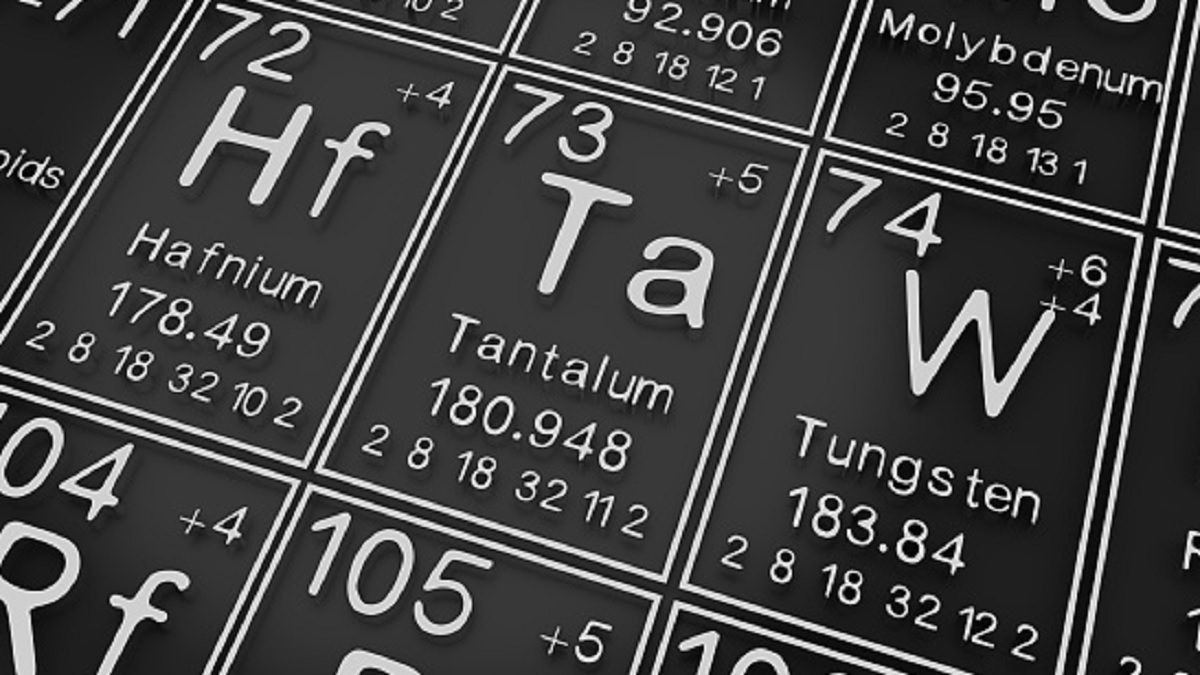

Behind the sophistication of smartphones, laptops, electric vehicles, and even modern aircraft, there are essential materials that rarely gain public attention—Tantalum and Tungsten. These two elements have unique properties that make them the backbone of modern technology.

This article explores in depth how Tantalum and Tungsten are used, why they are vital, and the future prospects of their role in global technological development.

The Advantages of Tantalum

Tantalum is well known for its exceptional resistance to corrosion. It can withstand almost all types of acids, making it an ideal choice for the chemical industry and medical technology. However, the most massive use of Tantalum is in the production of electronic capacitors. Nearly all modern smartphones and laptops use Tantalum-based capacitors because they are small yet capable of storing significant amounts of energy.

In addition, Tantalum is widely used in surgical equipment and medical implants. Its resistance to body fluids makes it biocompatible, meaning it can be placed inside the human body without causing negative reactions.

The Strength of Tungsten

Tungsten, on the other hand, is known as the metal with the highest melting point in the world—3,422°C. This property makes it indispensable in heavy industries, from manufacturing precision cutting tools and drilling machines to aircraft components. Tungsten was once used in light bulb filaments, though that role has now been largely replaced by LEDs.

In the era of electric vehicles, Tungsten is gaining renewed attention as a material for electrodes and durable battery components. Its combination of mechanical strength and thermal stability makes Tungsten difficult to replace in the technology industry.

Role in the Electronics Industry

Both Tantalum and Tungsten are key materials in the electronics industry. Tantalum is present in almost all modern communication devices, while Tungsten is used in semiconductor components, connectors, and radiation shielding.

Every time you switch on your smartphone, you are most likely using a product that depends on Tantalum and Tungsten. Without these two materials, modern devices would not be as efficient, compact, or advanced as they are today.

Driving Future Innovation

As the Internet of Things (IoT), artificial intelligence (AI), and electric vehicles (EVs) continue to expand, the demand for Tantalum and Tungsten is expected to rise. Tantalum will play a greater role in the development of compact, high-performance chips, while Tungsten will support innovations in energy storage and aerospace technology.

Global Supply Challenges

Despite their growing importance, the global supply of Tantalum and Tungsten is relatively limited. Producer countries such as Rwanda, the Democratic Republic of Congo, and China dominate the supply chain. This creates geopolitical challenges as well as sustainability issues.

To address this, global companies are now racing to recycle Tantalum and Tungsten from used devices. This effort not only helps secure supply but also reduces the environmental impact of excessive mining.

Tantalum and Tungsten are the invisible pillars of modern technology. From the smartphone in your hand to the aircraft flying across the sky, these two materials play vital roles. Looking ahead, as high-tech industries continue to advance, the demand for Tantalum and Tungsten will only grow stronger.

Understanding the roles and challenges associated with Tantalum and Tungsten is essential to realizing how the technologies of the future will be built.