In today’s modern industrial era, manufacturing plants are not only required to produce high-quality products but also to manage production waste wisely. Environmental challenges in urban areas encourage companies to seek innovative solutions that keep operations efficient without leaving harmful impacts.

One effective approach is turning production waste into a new source of revenue. This case study explores how a manufacturing plant in an urban area successfully improved profits through creative and sustainable strategies, including carbide recycling.

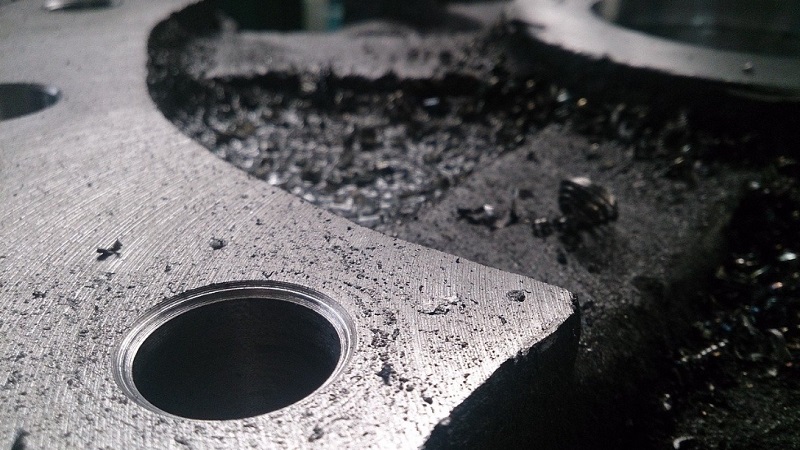

The Plant and Its Waste Problem

This automotive-sector plant produces thousands of machine components every month, requiring precision metal cutting. The process generates more than 10 tons of carbide waste monthly.

Initially, this waste piled up in warehouses without any purpose. The company even spent around IDR 200 million annually for storage and disposal. Like many factories, management considered carbide waste a burden rather than an asset. That perception shifted once they explored sustainability programs focused on carbide recycling and capturing the real tungsten scrap price in the market.

Identifying the Value of Carbide Waste

An environmental and production audit revealed that carbide waste contained valuable tungsten. Tungsten is highly demanded in the electronics, metal, and energy industries due to its durability, heat resistance, and high melting point.

Read More: What Determines Your Tungsten Carbide Scrap Price? Understand the Key Factors

When sold through carbide recycling channels, tungsten can be worth millions of rupiah per ton. Recognizing this highlighted the true tungsten carbide scrap value, showing that waste could become a strong revenue stream instead of a liability.

Waste Management Strategy

The company built a structured plan to manage carbide waste, focused on four steps:

- Systematic Waste Segregation – Creating special storage to separate carbide waste from other materials and maintain quality.

- Collaboration with Recycling Partners – Partnering with licensed metal recyclers specializing in industrial waste management, ensuring compliance and steady prices.

- Long-Term Business Model – Using annual contracts for carbide sales, reducing the risks of price fluctuations.

- Internal Reuse Innovation – Part of the carbide waste was reused internally, lowering reliance on new raw materials.

By combining internal reuse and external carbide recycling, the plant maximized both efficiency and revenue potential.

Program Implementation

The transformation required investment of about IDR 1 billion for storage facilities, sorting systems, and employee training.

Employees were trained to recognize the economic benefits of recycling carbide waste, making them part of the sustainability initiative. IoT-based systems tracked waste volumes in real time, helping management monitor contributions to overall revenue and understand changes in tungsten scrap price.

Results Achieved

Within one year, the plant achieved remarkable outcomes:

- 12% Additional Revenue – Carbide recycling generated IDR 15 billion annually.

- 8% Cost Efficiency – Waste storage and disposal costs dropped significantly.

- Positive Image – Recognition from city authorities as a leader in green manufacturing.

- Environmental Contribution – Over 70% reduction in waste going to landfills.

These results show how focusing on tungsten carbide scrap value and proper industrial waste management can yield tangible profits.

Challenges Faced

Despite success, challenges arose:

- Internal resistance from employees skeptical about extra workload.

- High initial investment for infrastructure.

- Fluctuating tungsten scrap price, requiring stable long-term contracts.

Through commitment and partnerships, the company overcame these issues.

Key Success Factors

The program succeeded because of:

- Strong management commitment.

- Strategic partnerships with certified recyclers.

- Innovation through partial internal reuse.

- Transparent monitoring with digital tools.

Long-Term Impact

The initiative had lasting impacts:

- Diversification into new waste management businesses.

- Cultural shift as employees embraced carbide recycling as opportunity.

- Easier compliance with environmental regulations.

- Competitive advantage from an eco-friendly reputation.

This case study proves that urban manufacturing plants can generate significant income by focusing on carbide recycling and understanding tungsten carbide scrap value. What was once seen as waste has now become a profitable asset.

By combining sustainability with profitability, companies not only boost revenue but also reduce environmental impact and strengthen their industrial reputation. With more manufacturers adopting this model, Indonesia’s industry could become a global example of how industrial waste management drives both economic growth and environmental protection.