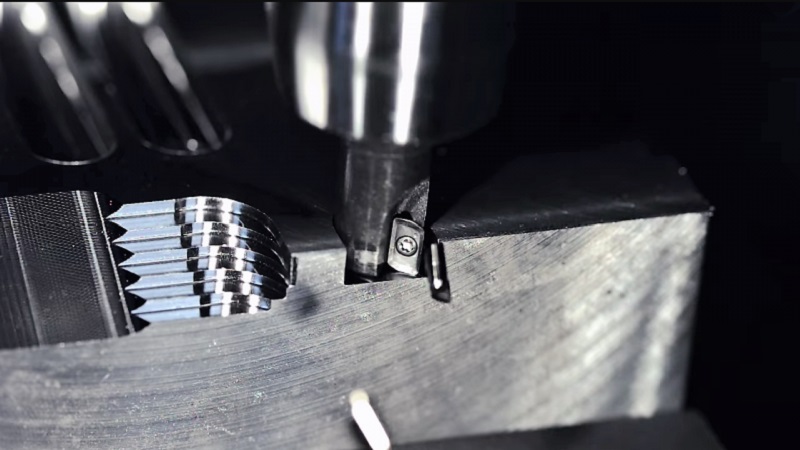

Determining the tungsten carbide scrap price is not as simple as weighing and selling it. Several important factors influence its value—from material purity, scrap form, to global market conditions. Tungsten carbide is known as an extremely hard, wear-resistant material, widely used in manufacturing, machining, and mining industries.

Because of its high value, even its scrap carries significant profit potential when managed properly. This article explains in detail the factors that determine the tungsten carbide scrap price, helping you secure the best possible offer. With the right knowledge, you can optimize sales value and avoid losses due to market fluctuations or poor material quality.

1. Material Purity – The Main Value Driver

Purity is the most critical factor in determining the tungsten carbide scrap price. Pure tungsten carbide typically contains 94–97% tungsten, with the rest being cobalt or other binders. The higher the tungsten content, the higher the price.

- 95% purity: Can fetch premium pricing because recycling efficiency is high.

- 80% purity: May be 20–30% lower than premium scrap prices.

Expert tips:

- Separate scrap by type and purity.

- Use a lab test or XRF analyzer to confirm tungsten levels.

- Avoid mixing high-grade scrap with lower-grade material.

2. Volume – The Benefits of Economies of Scale

The quantity of scrap you sell also affects the tungsten carbide scrap price. Larger transactions often command a higher price per kilogram because buyers save on logistics and processing costs.

- 500 kg scrap: More likely to secure a better rate.

- 5 kg scrap: Typically valued lower due to overhead costs.

Expert tips:

- Collect scrap over time until you have a significant volume.

- Partner with other suppliers to combine lots for better pricing.

3. Global Market Conditions – The Uncontrollable Factor

International market conditions play a huge role in the tungsten carbide scrap price. Fluctuations in raw tungsten prices, global demand, geopolitical risks, and currency exchange rates can all cause prices to rise or fall sharply.

Read More: From Your Warehouse to the Global Market: The Process of Selling Scrap to PT Bimantara

External influences include:

- Export policies of tungsten-producing countries (e.g., China).

- Trade wars or geopolitical conflicts.

- USD exchange rate against local currencies.

- Demand trends in technology and manufacturing industries.

Expert tips:

- Track the International Tungsten Industry Association (ITIA) price index.

- Hold stock during market downturns and sell when the trend improves.

- Build relationships with buyers connected to export markets.

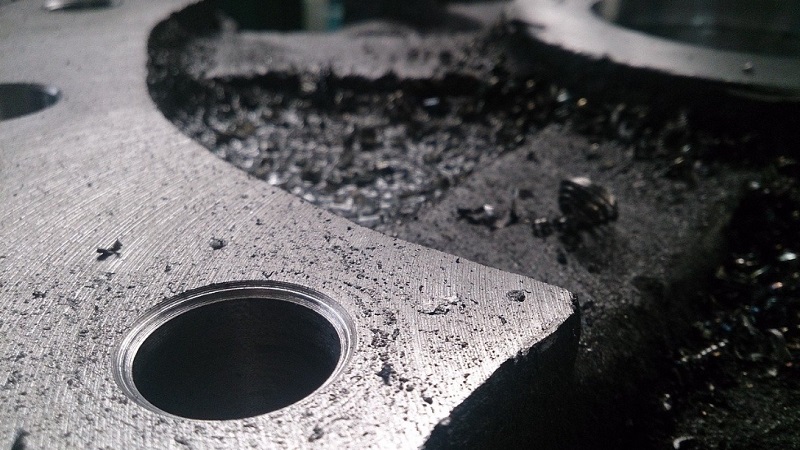

4. Level of Contamination – The Hidden Cost Factor

Contamination can significantly lower the tungsten carbide scrap price. Scrap mixed with oils, coatings, or other metals requires extra cleaning or separation, which increases buyer costs.

Common contaminations:

- Scrap coated with paint or protective layers.

- Mixed with steel, copper, or aluminum.

- Containing industrial oils or lubricants.

Expert tips:

- Clean your scrap before selling.

- Use safe mechanical or chemical methods to remove oils or coatings.

- Separate carbide scrap from non-carbide materials early.

Why Prices Differ Greatly

Sellers often wonder why one deal yields a premium price while another does not. The answer lies in the combination of the four main factors: purity, volume, global market conditions, and contamination.

- Seller A: 98% pure scrap, 300 kg, clean, sold during market highs → Premium price.

- Seller B: 85% purity, 20 kg, contaminated, sold during market lows → Low price.

The tungsten carbide scrap price is never random—it reflects the true quality and market conditions. Sellers who manage these factors well consistently achieve higher profits.

Understanding the key drivers behind the tungsten carbide scrap price gives you a competitive edge. By maintaining high purity, collecting significant volumes, ensuring cleanliness, and timing sales with favorable market trends, you maximize your returns.

With the right strategy, you won’t just receive a fair price—you’ll also build a reputation as a professional and trustworthy supplier in the global scrap metal market.